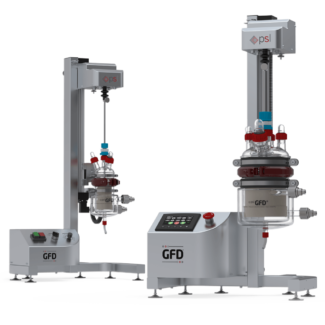

GFD Lab (500 Series) - Agitated Nutsche Filter-Dryer

The GFD Lab, from our partner Powder Systems, is the only automatable benchtop Agitated Nutsche Filter-Dryer. It is designed to perform efficient, repeatable and scalable laboratory solid-liquid separation processes. Key benefits include:

- Combined filtration and drying in a single system: Slurry Filtration, Washing, Re-slurry, Vacuum Drying, Sampling, Discharge

- Unique filtration basket to enable quick filtration media changeover whilst maximising product recovery.

- Adaptable, sector-specific solutions with multiple vessel sizes and product contact materials to fast-track process and scale-up activities.

- Complete process control with data acquisition and recording features for consistent and predictable results, batch after batch.

Selecting the right process technology at R&D stage is crucial to ensure your ultimate scale-up success. Our GFD®Lab product range was designed to streamline your scale-up development, from early R&D activities to GLP batches and pilot plant production. It is the perfect tool to complete scale-up and scale-down studies as it will help you maintain – at every scale – your key process objectives (e.g. product quality, product yield, batch consistency, etc.) and key production parameters (e.g. filtration time, washing time, drying time, etc.).

The GFD®Lab PLUS is designed for scaled-up, automated development where building bespoke process sequences and optimising process recipes to suit your own process application is possible.

Both the GFD lab and the GFD Lab Plus offer the unique features of Powder System’s Lab Filter Dryer. They are available as the 010 Series (vessel volume: 0.3l, maximum cake volume: .1l), 050 Series (vessel volume: 2l, maximum cake volume: .5l) and 500 Series (vessel volume: 10l, maximum cake volume: 5l).

NEED EXPERT ADVICE? LEARN MORE