Eddy Current Flaw Detectors

Evident‘s portable eddy current (EC) flaw detectors inspect metallic parts and perform highly reliable and advanced flaw detection of surface and near-surface defects. Evident offers portable eddy current equipment to meet a broad range of applications, including the detection of surface or near-surface defects, and the inspection of bolt holes. This eddy current testing equipment includes the latest advances in eddy current flaw detection for precise use in various inspection applications. In an eddy current inspection job, you need equipment you can trust. Evident’s eddy current flaw detectors are built with endurance in mind and are field-proven to withstand even the most demanding conditions.

FEATURED PRODUCTS

Evident converges its latest advancements in high-performance digital circuitry and eddy current flaw detection into one compact and durable portable ...

More About NORTEC 600 | Eddy Current Flaw Detector

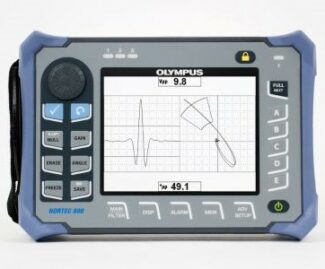

NORTEC 600 | Eddy Current Flaw Detector

Evident converges its latest advancements in high-performance digital circuitry and eddy current flaw detection into one compact and durable portable unit—the new NORTEC® 600. With its crisp and vivid 5.7 inch VGA display and true full-screen mode, the NORTEC 600 is capable of producing highly visible and contrasting eddy current signals in any lighting condition.

The redesigned interface of the NORTEC 600 borrows the intuitive, knob-operated navigation of its NORTEC predecessors and combines it with the simple menu structure and highly efficient direct-access keys of other popular Olympus instruments. Available in four versatile models, the NORTEC 600 offers a wide range of innovative functionalities, including an Application Selection menu, an all-in-one display, real-time readings, and signal calibration in Freeze mode, ensuring that inspections are quick and easy for any level of operator.

NORTEC 600 overview

- Reliable and Robust: Based on an already field-proven instrument case, the NORTEC 600 is built for endurance in harsh field conditions. Its casing’s durability and resistance to extreme weather makes the NORTEC 600 an instrument you can trust for any eddy current inspection job.

- Portable and Lightweight: The NORTEC 600 weighs only 1.6 kg and is delivered with a factory-installed hand strap that provides direct thumb access to the key controls, offering genuine handheld versatility to operators.

- Four Models for All Your Needs: The NORTEC® 600 is available in four versatile instrument models to meet the widest range of inspection needs. From the basic model upward, each unit unlocks more features. For maximum convenience, additional features can also be unlocked remotely.

- Vibrant VGA Display: The NORTEC® 600 has one of the most brilliant displays available on the portable eddy current flaw detector market. The unique brightness, resolution, and definition of its 5.7 inch VGA display makes it possible to interpret eddy current signals at a distance. The user-selectable color schemes ensure that the display is equally clear and easy-to-read whether you are using the NORTEC 600 indoors or outside.

NORTEC 600 Eddy Current Flaw Detector features

- Designed to meet the requirements of IP66.

- EN-15548 compliant.

- Long battery life (up to 10 hours).

- Bright, 5.7 inch (14,5 cm) VGA display.

- Full-screen option in any display mode.

- Improved filters for rotary scanner mode.

- Intuitive interface with Application Selection presets.

- All-settings configuration page.

- 10 Hz to 12 MHz frequency capacity.

- Automatic internal balancing (BNC connector).

- Up to two real-time readings.

- True automatic mixing.

- Storage capacity of up to 500 files (program and data).

- On-board file preview.

With thousands of units being used throughout the world, the Evident OmniScan MX is a field-proven, reliable instrument that is built to withstand har...

More About OmniScan MX ECA/ECT | Eddy Current Array

OmniScan MX ECA/ECT | Eddy Current Array

With thousands of units being used throughout the world, the Evident OmniScan MX is a field-proven, reliable instrument that is built to withstand harsh and demanding inspection conditions. Compact and lightweight, its two Li-ion batteries provide up to 6 hours of manual or semi-automated inspection time.

The highly legible 8.4 in. (213 mm) real-time color display of the OmniScan MX enables you to see defects and details under any light conditions. Navigate your way through the instrument’s simple and intuitive interface using the scroll knob and function keys, or by connecting a USB mouse to facilitate the inspection analysis.

OmniScan MX overview

- One Platform, Two Modules, Three Technologies: To meet the requirements of a broader range of applications, eddy current testing (ECT), eddy current array (ECA) and the new bond testing (BT) C-scan technology are available in two module versions. Both of these modules are compatible with the MXE (ECT/ECA) and MXB (BT C-scan) software, providing easy transition between technologies and a very short learning curve.

- Large Coverage, Fast Scanning, and Higher Probability of Detection: Eddy current array (ECA) technology incorporates several traditional bridge or reflection (driver-pickup) probe coils in order to achieve a much larger coverage in a single inspection pass. Additionally, each ECA probe model is carefully designed to maintain a high probability of detection of a targeted defect range, all along the probe length. With the OmniScan® MX ECA, you can use ECA probes at fast manual-inspection speeds, offering a powerful and productive inspection with color representation and archiving capability.

OmniScan MX applications

- Stress Corrosion Cracking Solutions: Olympus offers a range of productive solutions to detect or evaluate the depth of surface-breaking stress corrosion cracking. These solutions are based on the OmniScan MX ECA, a powerful and easy to use eddy current array flaw detector.

- Doubler Edge Skin Crack Inspection Solution: The Doubler Edge Skin Crack Inspection solution utilizes the latest ECA technologies for subsurface detection. The C-scan allows for higher probability of detection and better reproducibility. This solution is a major step forward in terms of reduced inspection time.

- ECA Surface Crack Detection: The Surface Crack ECA solution proposes an ergonomically-improved version of the SBBR-026 high-resolution ECA probe. This solution detects surface-breaking cracks at a very productive rate, even through paint and thin coatings. This is particularly well-suited for performing fast inspections of aircraft fastener rows.

- ECA Subsurface Crack Detection: The Subsurface Crack ECA inspection solution is capable of scanning through the first aircraft layer (skin) to detect cracking present on the 2nd layer, without the need for paint removal. This solution is available in two ECA probe versions (commercial and military aircrafts), both covering at least 64 mm in a single pass.

- ECA Subsurface Corrosion Detection: The Subsurface Corrosion ECA inspection solution performs rapid inspection of large areas for potential corrosion. Available in two probe versions (commercial and military aircrafts), this solution can evaluate the severity of hidden corrosion (defect depth) in an instant, without the need for paint removal.

- Carbon Steel Surface Examination: The MagnaFORM™ eddy current array solution enables users to inspect through paint and rough surfaces. The dynamic lift-off compensation helps ensure that the sensitivity to surface-breaking defects is maintained on the roughest of welds and corroded areas.