OmniScan | Phased Array Flaw Detectors

Evident OmniScan phased array instruments provide precise measurement with the most reliable results. Our range of OmniScan phased array devices produce accurate, detailed cross-sectional pictures of internal structures at fast inspection speeds. Here you can find phased array equipment and instruments including flaw detectors, scalable acquisition units, and phased array inspection software to work alongside your phased array device. These powerful tools allow you to complete even the most demanding inspections with confidence, offering precise data acquisition, visualisation and analysis of ultrasonic signals. Our phased array equipment and phased array software solutions are fully integrated, with fast calibration and streamlined user interfaces so you can complete your setup and inspection in minimal time.

FEATURED PRODUCTS

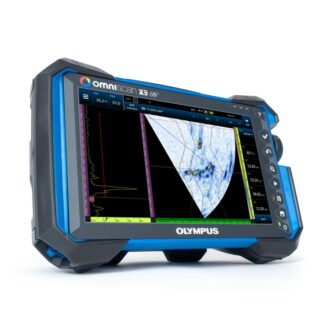

The Evident OmniScan X3 flaw detector is a complete phased array flaw detector. Powerful tools, like total focusing method (TFM) images and advanced ...

More About OmniScan X3 Series | Phased Array Flaw Detector

OmniScan X3 Series | Phased Array Flaw Detector

The Evident OmniScan X3 flaw detector is a complete phased array flaw detector. Powerful tools, like total focusing method (TFM) images and advanced visualization capabilities, enable you to complete your inspection with greater confidence. Twice as fast as the OmniScan MX2 (pulse repetition frequency) it offers Innovative TFM and Improved Phased Array. Its range of applications include welds, pipelines, pipes, corrosion-resistant alloys, corrosion mapping, HTHA inspection, detection of stepwise cracking, composite inspection, and flaw imaging.

OmniScan X3 Phased Array Flaw Detector overview

Improved Phased Array

- Up to 3x as fast as the OmniScan MX2 flaw detector (max pulse repetition frequency)

- Single TOFD menu for an accelerated calibration workflow

- 800% high amplitude range reduces the need to rescan

- Onboard Dual Linear Array™ and Dual Matrix Array™ probe support accelerates setup creation

Ease Corrosion Monitoring Using Phased Array

Using phased array to inspect corrosion offers many benefits, including excellent coverage and resolution. However, becoming proficient in phased array techniques can be challenging. The OmniScan X3 flaw detector combines advanced functions such as gate synchronization with thoughtfully designed software and simplified menus, so you can obtain accurate data more easily. Configure your setup quickly thanks to its A-scan synchronization processing and manual time-corrected gain (TCG).

OmniScan X3 Phased Array Flaw Detector with Innovative TFM

The OmniScan X3 flaw detector is a complete phased array toolbox. Powerful tools, including total focusing method (TFM) imaging and advanced visualization capabilities, backed by its high image quality enable you to complete your inspection with greater confidence.

OmniScan X3 64 Phased Array and TFM Flaw Detector with Advanced Capabilities

Housed in the field-proven rugged and portable OmniScan X3 enclosure, the OmniScan X3 64 flaw detector’s powerful focusing capabilities supported by its larger element-aperture capacity enable you to fully exploit 64-element phased array probes and 128-element aperture TFM. Utilize its enhanced performance to meet the inspection challenges of thick and attenuative materials and expand your potential to develop new procedures for a wider range of applications.

Benefit from 64-Pulser Phased Array

Exploit the full potential of 64-element phased array probes using the OmniScan X3 64 flaw detector to achieve improved resolution at the focal point.

Slide Right: Acquired using a 32-channel OmniScan X3 unit with a 64-element probe (5L64-A32 model), this S-scan is a high-quality image but the resolution reflects the fact that only the middle 32 elements could be used for the focal law.

Slide Left: Using a full 64-element aperture (5L64-A32 probe), the OmniScan X3 64 flaw detector provides better PA resolution at the focal point, enabling you to more easily distinguish indications that are close together or in a cluster.

The Evident OmniScan SX is a flaw detector that benefits from more than 20 years of phased array experience and shares the OmniScan DNA. For improved ...

More About OmniScan SX | Phased Array Flaw Detector

OmniScan SX | Phased Array Flaw Detector

The Evident OmniScan SX is a flaw detector that benefits from more than 20 years of phased array experience and shares the OmniScan DNA. For improved ease of use, the OmniScan SX features a new streamlined software interface displayed on an 8.4 in. (21.3 cm) touch screen. A single-group and non-modular instrument, the OmniScan SX is easy to operate and cost-effective for less demanding applications.

OmniScan SX Phased Array Flaw Detector overview

- Two models are available: the SX PA and SX UT. The SX PA is a 16:64PR phased array unit, which, like the UT-only SX UT, is equipped with a conventional UT channel for pulse-echo, pitch-catch or TOFD inspection. Compared to the OmniScan MX2, the SX is 33% lighter and 50% smaller, offering an unprecedented level of portability for an OmniScan.

- Touchscreen offers a full-screen mode option that maximizes visibility essentially converting many menu functions into easy touch-screen operations. The intuitive interface provides smooth menu selection, zooming, gate adjustments, cursor movements, and text and value input. These, along with other premium integrated features, including easy-to-follow setup and calibration Wizards, a rapid refresh rate for both the S-scan and A-scan displays, and a fast pulse repetition frequency (PRF), make the OmniScan SX a highly efficient inspection tool.

- Fully compatible with the extensive portfolio of Olympus scanners, probes and accessories and with its dedicated software companions, NDT SetupBuilder and OmniPC. Combined, the complete family of software and hardware contributes to a streamlined and efficient inspection workflow, from design and setup to acquisition and analysis.

OmniScan SX software features

The new OmniScan software features enhancements for greater functionality in weld and corrosion markets. In the effort for continuous improvement, the software interface was simplified and the response time optimized in order to provide the best experience possible for customers.

- Export C-Scan

- New End-View with group merge

- Interleave

- Analysis attenuation gain

- Scrolling layouts for easy interpretation

- Improved accessibility with more interactive menus

- Optimised main menus and wizards

- Onboard compound scan

- Curved geometry ray-tracing for longitudinal welds

OmniScan SX applications

The Omniscan SX provides Olympus with a new and versatile tool to add to its arsenal of innovative and creative complete market solutions aimed at simplifying your workflow and improving overall productivity.

- Phased Array Weld Inspection: The OmniScan PA is at the heart of the manual and semiautomated phased array weld inspection solutions developed by Olympus for the oil and gas industry. These systems can be used for inspection in compliance with ASME, API, and other code criteria, while offering high-speed detection capabilities, and facilitating indication interpretation.

- Corrosion Mapping and Composite Inspection: Zero-degree inspection just became even more accessible with the arrival of the OmniScan SX. For corrosion or composite inspection, Olympus offers field-proven solutions for detection of anomalies or wall loss.

- TOFD Weld Inspection: TOFD is an easy and efficient approach for primary detection of weld defects. It is quick, cost-effective and capable of sizing defects present in the volume of the weld, a problematic area for manufacturing defects.

- Component Inspection: Using ultrasonic techniques, inspection of components can detect cracks, wall loss, and other damage. With the capacity for both angle and linear zero-degree beams, the OmniScan SX is a very cost-efficient solution for this type of single-group inspection.