Exploring Texture Analysis in advancing Medical Device Product Development

The medical device industry thrives on constant innovation, fuelled by collaborative efforts across engineering, clinical, and biological domains. Ireland’s significant role in the global medtech sector adds a unique dimension to this innovation landscape. As technology evolves and our understanding of human biology deepens, the field continues to witness groundbreaking advancements.

Medical Device Product Research, Development and Production

The medical device landscape is always evolving, with a focus on enhancing patient outcomes, minimising invasiveness, and integrating the latest technological trends.

Here we look into some emerging material and product concepts currently shaping the medical devices industry:

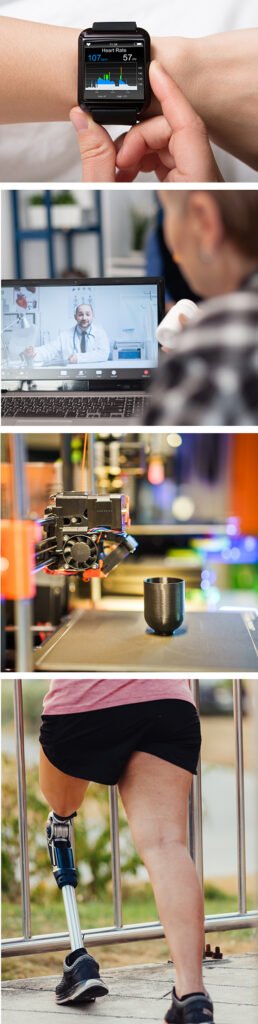

- Wearable Medical Devices: These include smartwatches and wearables designed to monitor real-time health metrics such as heart rate, blood pressure, and oxygen levels.

- Bioabsorbable Implants: Implants engineered to be gradually absorbed by the body over time, obviating the need for surgical removal.

- Telehealth Devices: Facilitating remote patient monitoring and consultations, thereby reducing the necessity for in-person visits.

- 3D Printed Medical Devices: Utilising 3D printing for personalized prosthetics, implants, and even tissues.

- Robot-Assisted Surgery: Robotic systems augmenting precision and control during surgical procedures.

- Nano-sized Devices: Leveraging nanotechnology for targeted drug delivery or in-body imaging.

- Smart Implants: Implants embedded with sensors for relaying environmental or status information.

- Biocompatible Materials: Novel materials designed to interact favourably with the human body, including bio-based and advanced polymers.

- Lab-on-a-chip Devices: Miniaturised devices capable of conducting complex laboratory tests on a single chip, enhancing efficiency, and reducing costs.

- Decentralised Diagnostic Devices: Point-of-care diagnostic devices, minimising the need to send samples to centralised labs.

- Shape Memory Alloys: Metals reverting to their original shape when subjected to specific stimuli, ideal for devices like stents or guidewires.

- Hydrogels: Water-swollen polymers with diverse applications in drug delivery, wound care, and tissue engineering.

- Conductive Polymers: Employed in flexible electronics, sensors, or neural interfaces due to their electrical conductivity and biocompatibility.

- Smart Materials: Materials exhibiting property changes in response to external stimuli, facilitating applications in drug delivery systems and adaptive implants.

- Drug Delivery Devices: Innovations such as microneedle patches, implantable drug reservoirs, or responsive systems releasing drugs in response to specific stimuli.

Leveraging Texture Analysis for Advancement: Testing Critical Material Attributes of Medical Devices

In the realm of medical device research and development (R&D), the Texture Analyser emerges as a pivotal tool, enabling comprehensive evaluation and enhancement of critical material attributes. Let’s explore its versatile applications:

The analysis of tensile strength offers profound insights into the robustness and elasticity of flexible medical devices such as sutures, catheters, and more.

Adhesion strength assessments extend to adhesive medical products, including wound dressings and patches, facilitating a nuanced understanding of bonding capabilities.

The Texture Analyser’s applicability encompasses the examination of compression and hardness, vital for implants and padded devices, elucidating resistance to compressive forces and hardness characteristics.

Evaluations of needle penetration dynamics measure the force requisite for needle penetration through skin or tissues, particularly relevant for devices like syringes. The assessment of puncture and burst resistance extends to products like gloves, pouches, or bags, gauging the force they can endure before puncturing or bursting.

The Texture Analyser’s contributions further include shear resistance testing, which informs the response of materials or devices to shear forces, relevant for products that might encounter sliding or rotational forces.

For drug-eluting devices, the analysis of release force offers insights into the required force or pressure for drug release.

The assessment of frictional properties is pertinent for devices like catheters, ensuring efficient navigation through bodily tissues.

Additionally, the Texture Analyser extends its functionality to evaluate gel consistency and strength, particularly significant for hydrogel-based products and materials employed in diverse medical applications.

Swelling properties examinations delve into the behaviour of materials like hydrogels or other absorbent medical substances when exposed to fluids.

Check out the Stable Micro Systems Texture Analysers here.

Enhancing Medical Device Development through Texture Analysis Integration

Through collaborative integration with other testing methodologies, the Texture Analyser facilitates thorough material assessment, providing invaluable insights that steer formulation enhancements and drive the advancement of state-of-the-art medical devices. Texture analysis plays a pivotal role in ensuring adherence to stringent performance criteria, thereby elevating patient care standards. Given the direct interaction of medical devices with the human body, a profound understanding of their mechanical properties is imperative to guarantee desired functionality and mitigate potential complications.

This article was first published by our partner Stable Micro Systems in their Texture Analysis Professionals Blog. Click here to read the full article.

For more information:

Michael Kervick is a sales manager with specialist knowledge of the Stable Micro Systems range of products and their applications. Get in touch with Michael today if you would like further information on the Stable Micro Systems range of products including texture analysers.

Michael Kervick

E: mkervick@masontec.ie

M: +353 87 223 1979

RECENT POST

Introducing the Eppendorf Research® plus 4-Pack with e...

Apr 24, 2024

NewsMettler Toledo Launches New Generation of Laboratory Ba...

Apr 22, 2024

NewsMason Technology is one of Ireland's Best Workplaces&#x...

Apr 18, 2024

NewsWebinar: Thinking outside the mouse: ex-vivo dissection...

Apr 11, 2024

WebinarsUnderstanding Buffers in Liquid Chromatography

Apr 10, 2024

BlogExploring Texture Analysis in advancing Medical Device ...

Mar 26, 2024

BlogFreeze Drying Adviser Vol.2: Illustrated Toolkit for Ge...

Mar 13, 2024

White PapersSolvents Mixing Ratio in Liquid Chromatography

Mar 06, 2024

Blog