High-Performance TLC – The Dark Horse of Chromatography?

High-Performance TLC – The Dark Horse of Chromatography?

We all remember separating food colourings on flimsy silica sheets at University, for many scientists this is where we first learned the principals of chromatographic separation. Traditional Thin Layer chromatography (TLC) is perfect for this as it is visual, cheap and easy to do. But what many don’t know is that TLC has moved on in a huge way, so much so, that it may be the dark horse of the chromatography world?

When beginning my PhD research on the analysis of organic foods I didn’t even consider Thin Layer chromatography, I didn’t think it was sophisticated or novel enough to spark the interest of peer reviewers. Fast forward a few years I join Mason Technology and find myself responsible for a range of TLC instruments from a Swiss company called CAMAG. Visiting the CAMAG method development laboratory in Switzerland was like a light-bulb moment, I returned with so much enthusiasm for the technique and what it can offer to the research and quality control of natural products, pharmaceuticals and beyond.

So, what’s changed?

TLC, like LC, has graduated to HP-TLC, or High Performance-TLC. The solid phase has a smaller pore size for quicker and sharper separations. The instrumentation and software packs a serious punch in terms of reproducibility, automation and regulatory features. This modernisation is due to the innovations of CAMAG, who have nurtured the technique and developed some very impressive instruments and software. HP-TLC now offers some very interesting possibilities for research, and can also compete in the regulated environment. In fact, the United States Pharmacopoeia recognises it as the preferred method for the identification of drugs of plant origin.

Why HP-TLC from CAMAG?

HP-TLC is an open separation system, the chromatography can be viewed with the human eye either directly, after a chemical reaction (Derivitization) or via UV lamps. Every band you observe is a component of the sample, there are no ghost peaks or nuisance unidentifiable anomalies.

The solid phase is disposable after each analysis – you can’t block or damage it! This makes HP-TLC perfect for complex or ‘dirty’ samples. There is little to no sample preparation, an extract or liquid sample is simply applied directly to the silica. For this reason, HP-TLC is the technique of choice for natural extracts and herbal medicinal products, but its application range is incredibly diverse, covering pharmaceuticals, forensics, environmental analysis and more.

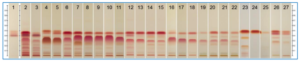

In the below example we see 27 natural and commercial forms of Cannabis sativa compared, the reproducibility of HPTLC allows for system suitability tests and hence comparisons of ‘fingerprints’ like this are possible.

Fig 1: Comparison of HPTLC fingerprints under white light after derivatization with FBS reagent. Samples include CBN, THC, CBD, hashish sample, C. sativa samples, C. sativa samples (young plants), CBD extraction, CO2-extracted CBD, CBD cream, Cannabis oil, and Cannabis tincture.

In HP-TLC all standards and samples are separated simultaneously, in parallel, using the natural capillary force of the solvent mobile phase traveling through the plate, therefore all samples have identical analytical conditions. Issues like drifts, shifts and pressure build up don’t exist. This coupled with the advancements in instrumentation and software allow for extremely reproducible results suitable for a cGXP environment. The speed of analysis is also impressive, on a standard HPTLC plate 15 samples and standards can be run in under 30 mins.

HP-TLC requires a tiny amount of solvent mobile phase per sample making it economical and environmentally friendly, there is also no requirement for filtration or degassing. The solvent evaporates before evaluation and doesn’t interact with the instrumentation, so you don’t need to consider if it is compatible with UV detection or if it is corrosive. The absence of solvent post-separation is also important for the recovery of separated components for Mass Spec or further analysis.

From a single separation we can evaluate using:

- UV-Vis and white light visualisation of bands (CAMAG TLC Visualizer 2);

- UV-Vis and Fluorescence Densitometry (CAMAG TLC Scanner 4);

- Bioluminescence (specific toxicity application via the CAMAG Bioluminizer) and

- Mass Spectrometry (HPTLC MS Interface 2).

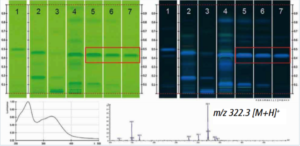

The MS hyphenation possibilities offer a particular advantage to research and compound discovery. The HPTLC MS Interface can be used with any MS or MS-MS detector. It requires no additional software, simply a HPLC pump and an MS detector of your choice.

Fig 2: HPTLC-MS used to identify ergoline psychedelics during chemical synthesis and purification.

All the advancements of HP-TLC are underpinned by one piece of well designed, intuitive software called VisionCATS. This software connects all CAMAG instrumentation as a suite which can be monitored and secured in line with 21CFR part 11 requirements and Data Integrity guidelines. The features of the software allow for full user administration, electronic sign-off and audit trail monitoring. VisionCATS has a well-established user base in regulated laboratories across Ireland since 2015.

Mason Technology are proud distributors of CAMAG HP-TLC instrumentation and software outlined in this blog. If you would like to learn more about optimising your current TLC methods or introducing the technique to your laboratory I would love to hear from you.

Rachel Tobin, PhD., Product Specialist at Mason Technology.

Rachel Tobin, PhD., is an Analytical Product Specialist at Mason Technology specialising in CAMAG High Performance Thin Layer Chromatography and Shimadzu Spectroscopy with postgraduate experience analytical biochemistry.

To learn more about HP-TLC, UV-Vis, FTIR or any other spectroscopy instrumentation you can contact Rachel via our contact us page, or e-mail directly at rtobin@masontec.ie

If you would like to stay in touch and receive updates on emerging and current laboratory technologies and receive our monthly blog posts register for our customer newsletter here.

RECENT POST

Mettler Toledo Launches New Generation of Laboratory Ba...

Apr 22, 2024

NewsMason Technology is one of Ireland's Best Workplaces&#x...

Apr 18, 2024

NewsWebinar: Thinking outside the mouse: ex-vivo dissection...

Apr 11, 2024

WebinarsUnderstanding Buffers in Liquid Chromatography

Apr 10, 2024

BlogExploring Texture Analysis in advancing Medical Device ...

Mar 26, 2024

BlogFreeze Drying Adviser Vol.2: Illustrated Toolkit for Ge...

Mar 13, 2024

White PapersSolvents Mixing Ratio in Liquid Chromatography

Mar 06, 2024

BlogMason Technology makes Ireland's Best Workplaces™...

Feb 29, 2024

News