Energy-Dispersive X-Ray (EDX) – Elemental Analysis in a Snap

Energy-dispersive X-Ray Spectroscopy (EDX) – revolutionising Elemental Analysis

The discovery of X-Ray radiation revolutionised the world of modern medicine. Its penetrating, high-energy properties allow for the visualisation of the human body, cancer treatments and more. When we think of X-Rays we usually think of the characteristic image of a broken bone, or even the contents of a suitcase at the airport. But X-Rays can also interact with objects on a smaller scale, the smallest in fact! At an atomic level, X-Ray energy can interact with the elements of almost any sample; and this phenomenon has been harnessed for laboratory techniques used for elemental analysis.

As part of my training at Shimadzu’s European HQ in Germany I was introduced to such a technique; Energy-dispersive X-Ray Spectroscopy, or EDX. EDX is a surface, simultaneous multi-elemental analysis technique that is non-destructive and requires no sample preparation. No mess, no filtering or harmful solvents. It uses a camera to focus the instrument on the area of interest, much like a sniper looking at a target in crosshairs. Then, in one quick measurement, it produces data on the entire elemental profile of the sample.

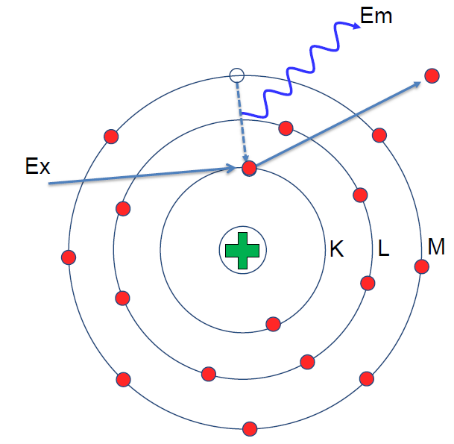

EDX- How does it work?

When the X-Ray source interacts with the sample it removes an electron which causes a ‘hole’, when this happens another electron from an outer shell takes its place – this loss of energy creates an emission that is characteristic of the element. The bigger the element the greater the energy that is emitted.

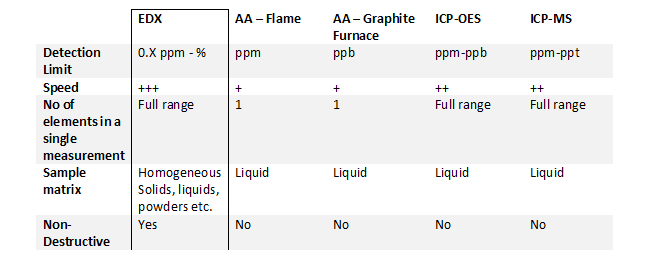

Why EDX vs Inductively Coupled Plasma (ICP) or Atomic Absorption (AA)

Like ICP (Inductively Coupled Plasma), EDX can analyse the full range of elements simultaneously in a single measurement, so it has this advantage over AAS (Atomic Absorption Spectroscopy) where elements must be measured one by one. Where EDX stands out is its flexibility and non-destructive nature – liquids, powders and solids can all be measured instantly. Due to its flexibility, EDX can be applied to any field of study – biological samples, drugs, raw materials, construction materials, metals, painted surfaces, electronics, food, precious metals and stones, environmental samples and more. If you don’t need the sensitivity of ICP, but you do need simultaneous elemental analysis, EDX is for you.

EDX Application Possibilities:

An Alternative Option for USP <233> for Elemental Impurities in Drugs

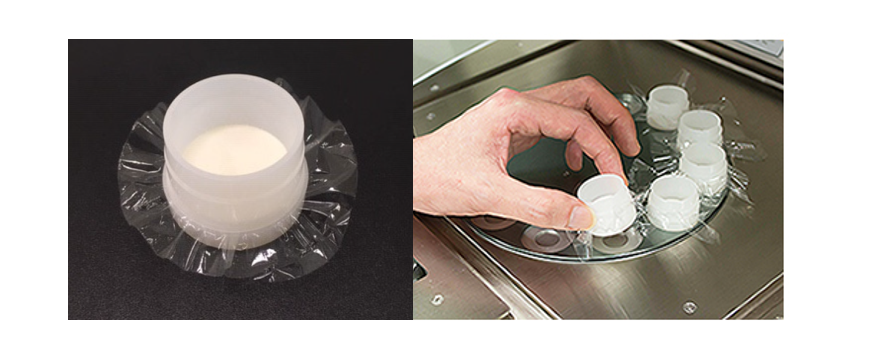

In the United States Pharmacopoeia general test chapters <232> and <233> for testing the elemental impurities As, Hg, Pb, Cd, V, Co, Ni and Pd in drug products, ICP techniques are recommended. However, an alternative technique can be used if it can be validated for use. Shimadzu have tested the appropriateness of using the EDX-7000/8000 for USP <233> testing by evaluating the elemental impurities in oral drug tablets in powder form according to the Limit Procedures in the chapter. The target concentration was 30% of the Permitted Daily Exposure (PDE) divided by the maximum daily dose of the drug. The EDX-7000/8000 passed all validation requirements and acceptance criteria of USP <233> which included detectability, specificity and repeatability. The ability of the EDX to measure a drug sample in powder form may represent huge cost and environmental benefits in terms of analyst time for sample preparations, instrument maintenance and overall cost, and solvent usage. Source: Shimadzu Application Note x273 USP 233 April 2020

Powder Sample and multi-sample turret in the EDX-7000

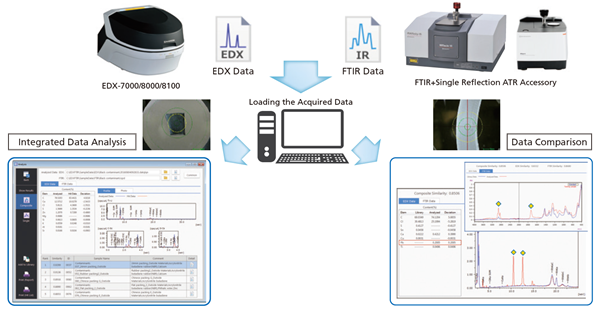

Foreign Materials Inspection with EDX-FTIR Combined Solution

FTIR, particularly with ATR is an extremely flexible analytical tool for investigative analysis of solid foreign materials found in manufactured products. FTIR will provide qualitative information on the organic chemical characteristics of a material almost instantly without preparation, and just as quickly match your sample spectra with a library to tell you what it is likely to be. This works particularly well for plastics and similar carbon-based materials. But where there are other non-organic materials present, for example metals and coatings, FTIR will not be useful and elemental analysis will be needed. Shimadzu have coupled up EDX and FTIR to provide a total solution for foreign material investigations. Two instruments, but a combined software package and library function to integrate the FTIR Spectra with the EDX elemental profile. The software library contains a wide range of data from common foreign matter such a coatings, glass, hair, nails and steel. The library can also be created to match the materials potentially encountered in a particular manufacturing environment.

Foreign Materials Inspection Process

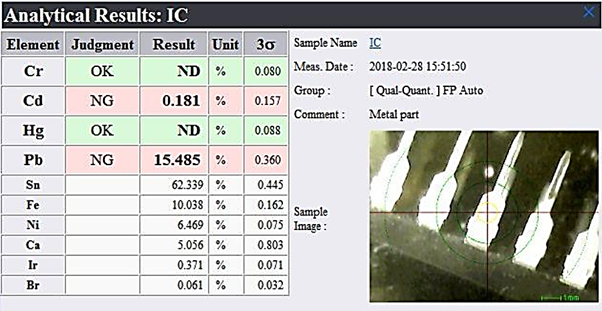

RoHS Directive Screening

RoHS stands for Restriction of Hazardous Substances; it applies to all electronic products and compliance is a prerequisite of CE-marking. EDX can be used to check parts of an electronic product by screening for the elements present in the 10 substances banned under RoHS 3. The EDX-7000/8000 is perfectly designed to test complex electronic parts for RoHS compliance as testing can be done on the assembled parts without destruction or preparation as long as the instrument can target one homogenous piece per measurement, as in the below example.

Mason Technology are proud distributors of Shimadzu EDX instrumentation including the EDX-7000 outlined in this blog. If you would like to learn more about EDX as a technique or introducing the technique to your laboratory I would love to hear from you.

Rachel Tobin, PhD., Technical Sales Consultant, Mason Technology.

Rachel Tobin, PhD., is an analytical product specialist at Mason Technology, specialising in CAMAG High Performance Thin Layer Chromatography and Shimadzu Spectroscopy, with postgraduate experience in analytical biochemistry.

To learn more about HP-TLC, UV-Vis, FTIR or any other spectroscopy instrumentation you can contact Rachel via our contact us page, or e-mail directly at rtobin@masontec.ie

If you would like to stay in touch and receive updates on emerging and current laboratory technologies and receive our customer newsletter sign-up here.

RECENT POST

Introducing the Eppendorf Research® plus 4-Pack with e...

Apr 24, 2024

NewsMettler Toledo Launches New Generation of Laboratory Ba...

Apr 22, 2024

NewsMason Technology is one of Ireland's Best Workplaces&#x...

Apr 18, 2024

NewsWebinar: Thinking outside the mouse: ex-vivo dissection...

Apr 11, 2024

WebinarsUnderstanding Buffers in Liquid Chromatography

Apr 10, 2024

BlogExploring Texture Analysis in advancing Medical Device ...

Mar 26, 2024

BlogFreeze Drying Adviser Vol.2: Illustrated Toolkit for Ge...

Mar 13, 2024

White PapersSolvents Mixing Ratio in Liquid Chromatography

Mar 06, 2024

Blog